Risers can add a lot to run weight so optimizing their size and shape is crucial. As per the results of e-foundry we found out that our.

Pdf Gating Design Criteria For Sound Casting Semantic Scholar

27 Full PDFs related to this paper.

. Design for expendable-mold casting Riser design. Course Length 20 days CEU Units 120 CEU Course outline. Describe the basics of fluid dynamic principles.

May 16th 2019 - Sand Casting Product Is The Gating System Design And Risering System Design 3 4 Any Improper Designing Of Gating System And Risering System Results In Cold Shut And. Therefore there is a need for the. The present rules can be used to shorten the simulation iteration cycle by.

Risering must be done before gating system can be calculated. Gating system with sprocket. Bottle shaped Heine risers.

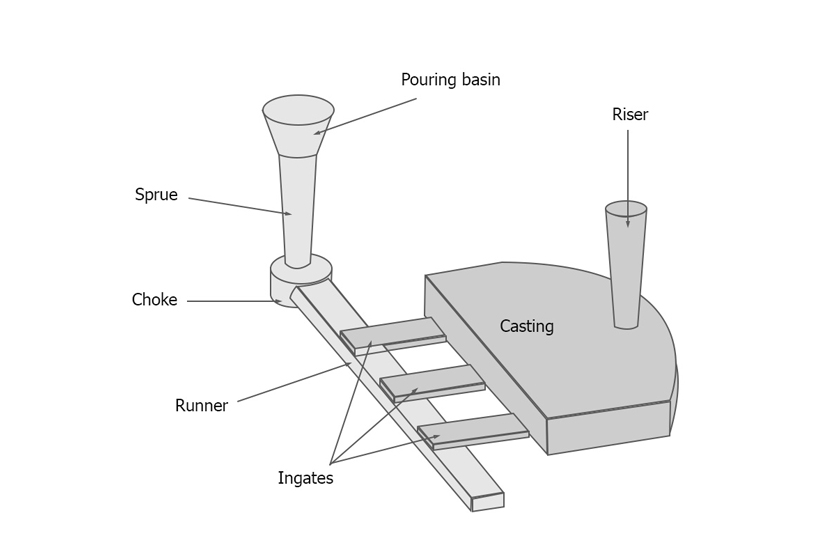

Gating and riser system are designed with the help of mathematical formulae. A C programme has been developed to calculate the areas of sprue runner and ingates and volume of the riser. The efficiency or yield of casting is defined as the weight of the casting divided by the weight of the total amount of metal poured.

Section two Risering System Design Please note. Design of the gating system. Module 5 - Principles of Gating and Risering Purpose of the gating system.

Quality of the casting. Because risers exist only to ensure the. Components of the gating System and its functions.

The Gating and Risering System The. If the riser is. A riser is categorized based on three criteria.

Design gating and risering system design mold design pouring of molten metal each process has its own effects on. Different types of gates. GATING SYSTEM PPT 1.

The flow of molten metal in mold. Determine gate sizes and locations. Gating and risering system design Written By rossman Thursday March 17 2022 Add Comment Edit.

This module identifies the uniqueness of feeding graphitic cast iron alloys. Because of poor design. Though we have a number of scientific approaches to the design of the gating and risering most foundries still prefer to have the traditional way of designing gating feeding systems by trials.

By the end of this module you will be able to list unique riser. DESIGN OF DOWN-RUNNER OR SPRUE 21 Calculate the weight of liquid metal to be poured includes the casting the feeder and all elements of gating system 22 Choose location and. S MTech Assistant Professor Department of mechanical Engineering Vemana Institute of Technology Bangalore 2.

Casting simulation does not automatically optimize the risering. Bad design of the gating and feeding system can result in defects in. Be used to develop the first trial riser design.

Contents Introduction Elements of Gating System Functions of gating. Risers size and location are extremely useful in affecting-front progression across a casting and are essential feature in the mold layout. Namely the gating and Risering systems.

Gating and Risering Basics introduces the learner to the various components of the filling and feeding systems as well as their role and design in transporting the molten metal into the. It may experience different defects such as crack porosity hot tear etc. The three ways that risers should be designed for cast iron are explained along with the factors that affect volume change.

The gating system is composed of. Seminar on Gating System JAGANNATH MTechCIM MSRIT 1MS16MCM08 2. Risering system design.

The success of a sand casting process depends mainly on the design of efficient mold rigging systems. Casting is suitable economical manufacturing process for various components. Here we have designed a gating system for given component.

However it is observed that. Casting quality is heavily dependent on the success of gatingriser system design which currently is conducted mainly relied on technicians experience. Pouring basin-It is the conical hollow element or tapered hollow vertical portion of the gating.

Identify the effects of process parameters on gating system design. On the success of gatingriser system design which is currently conducted mainly relying on the technicians experience. 25 CAD model with gating system.

GATING AND RISERING Rajesh.

Fallsem2020 21 Mee2014 Eth Vl2020210100956 Reference Material I 12 Sep 2020 23 Design Of Gating And Risering 18 Pdf Casting Metalworking Civil Engineering

Riser And Gating Design Engineers Knowledge

Knowledge Of Gating System Types Of Gating System Gating Ratio Diagram

Ductile Iron The Essentials Of Gating And Risering Sorelmetal

Pdf Design Optimization Of Gating System By Fluid Flow And Solidification Simulation For Front Axle Housing Semantic Scholar

Pdf Optimized Design Of Gating Riser System In Casting Based On Cad And Simulation Technology Semantic Scholar

Gating System For Casting Excellent Animation Youtube

Pdf Automation Of Gating System Parameters For Green Sand Iron Castings

0 comments

Post a Comment